3D printing has undoubtedly transformed the world of manufacturing. Whether that is by increasing productivity by reducing the time taken to complete tasks or driving financial efficiency in terms of removing the need to purchase expensive machinery. It goes without saying that it benefits each and every one of us, but would you know just how to use a 3D printer if it was in front of you? Here, I will explain the 3D printing process in relatively simple terms.

First of all, it should be noted that there are actually four types of 3D printing processes. They are as follows:

- SLS (Selective Laser Sintering)

- SLA (Stereolithography)

- MJM (Multi Jet Modelling)

- FDM (Fused Deposition Modelling)

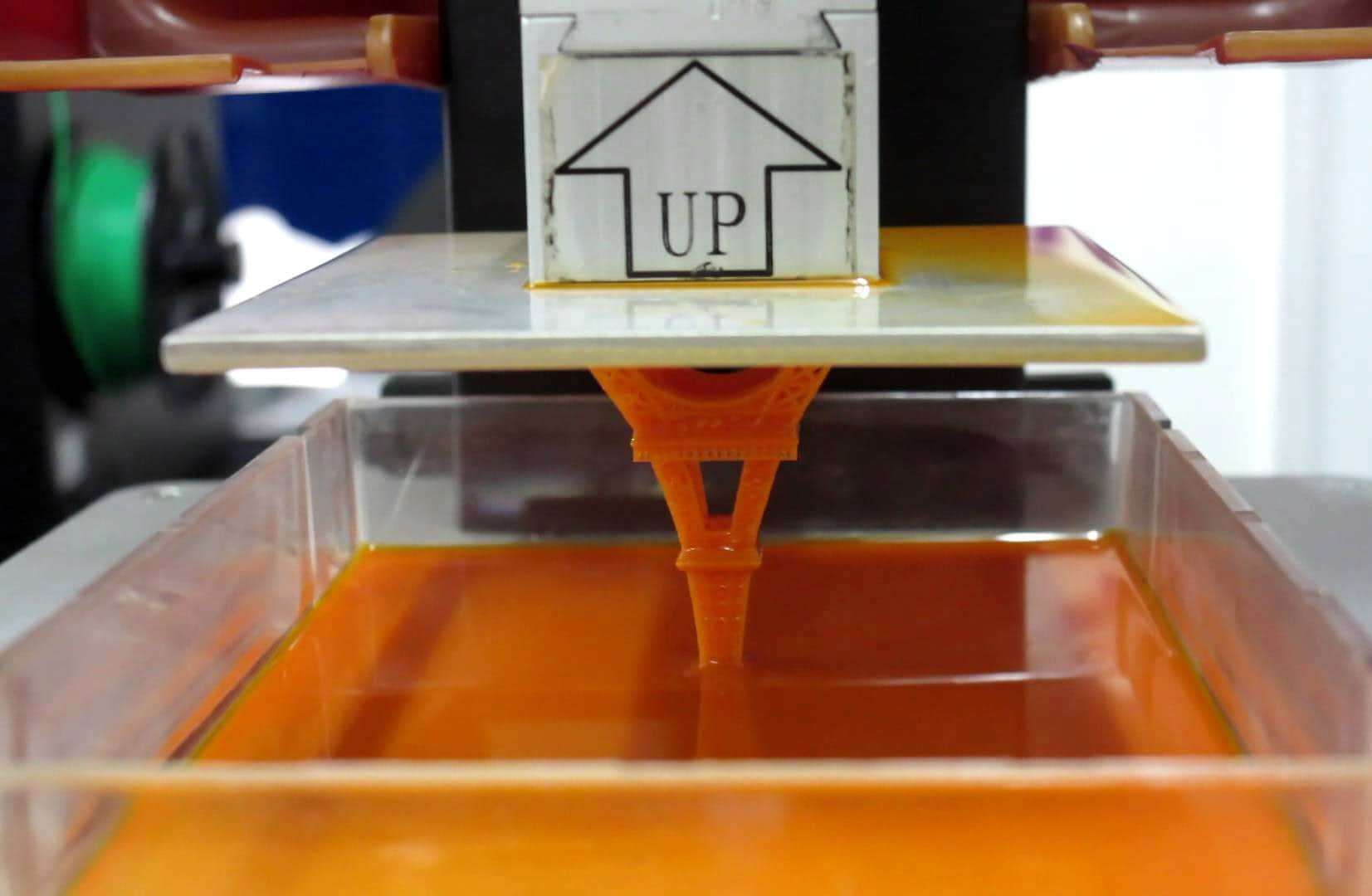

For the sole purposes of this article, I am only going to cover SLA (Stereolithography) and I’ll explain why. Stereolithography is openly recognised as the father of the 3D Printing processes. It was originally introduced and later patented by Charles. W. Hull, the inventor of 3D printing systems. The SLA process involves using photopolymer resin in its simplest liquid form and curing it layer by layer to create the finished product.

How Does 3D Printing Work?

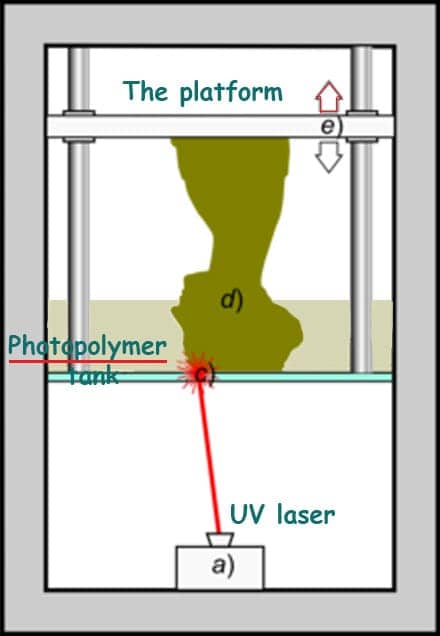

An SLA 3D printer usually consists of four main features that enable the printer to work successfully. These are:

- The photopolymer tank which houses the liquid plastic I discussed earlier. This can easily be refilled by the user.

- The platform. This is essentially submerged into the tank.

- The ultraviolet (UV) laser.

- The central computer that controls the moving elements of the 3D printer.

The first step of SLA printing involves a platform with many tiny holes being lowered to slightly expose a thin layer of the photopolymer solution. The UV laser is then specifically targeted at the perforated platform. This essentially draws the pattern of the design and forms the first layer of the desired product.

Once the primary layer has hardened sufficiently, the platform is lowered again. This then exposes a further layer of liquid plastic. The laser again draws the pattern of the design which instantly adheres to the earlier printed layer. This process is repeated time and time again until the desired product is completed. Naturally, the larger the product specification, the longer the process will take. However, it should be noted that this process is still far quicker and more cost-effective than it would be to manufacture the same product, using older fabricating processes. Once the process is complete, the 3D design is raised and washed with a solution to remove any excess photopolymer. To ensure the product is hardened, it is then baked in a UV kiln. This completes the SLA process.

The time it can take to manufacture certain designs can vary greatly. If the desired object is relatively small. It should be completed by a standard SLA printer in 2-10 hours. On the contrary, larger items can take as long as two or three days.

So just what can be manufactured using an SLA process? The medical industry has rightfully taken full advantage of progressions in 3D printing. To date, objects ranging from life changing prosthetic limbs to fully functioning tissues with blood vessels. Remarkable right? SLA printing has also revolutionised the automotive industry with the Italian company X Electrical Vehicle expected to launch fully 3D printed cars as early as 2019. So, while industries such as these are pioneering the way to a 3D printed future for us all to enjoy, we must consider how this kind of technology could be manipulated if it were to fall into the wrong hands.

So, what should you look for in a 3D printer and where would you even get one from? By far and away the leading manufacturer of SLA printers right now is Massachusetts-based company, Formlabs. Formlabs appeared on the hit Netflix documentary, ‘Print the Legend’ which focussed heavily on the rapid growth of 3D printing in recent times. Naturally, there are other companies out there, such as: 3D Systems, Printform and Stratasys to name a few. The first thing you need to consider when buying a 3D printer is of course, what is it that you want to print? If you are looking to work on small projects, then you would be fine to purchase one of the smaller, lower end models from any one of the companies I wrote about earlier. In contrast, if you were looking to take on a much larger project, then that would require a much larger 3D printer.

How to Choose a 3D Printer for Home

As the size of the 3D printer changes, so does the price. According to price comparison site, a lower end SLA printer can be picked up for as little as $250 USD whereas a higher specification model can sell for up to $5000 USD. Whilst there are enthusiasts actively experimenting with 3D printers at home, it could be years before everyday individuals show a genuine need for a 3D printer in their home but rest assured, the technology is here and we must be ready to embrace the future.

[amazon box="B07GPQP1SK,B07K33DCNW,B07BQ2K9V3,B078N2TSYS,B00ZKE559W,B06W9LMGG2" template="table"]

Leave a Comment